2019 News

Laboratory Construction: Helping Clients Make the World Better

Laboratory Construction: Helping Clients Make the World Better

Commercial and industrial laboratories come in all shapes and sizes. “They could be the size of a closet, a room or an entire facility. We’ve designed, built, automated, provided data systems and serviced them all,” says Gary Seymour, Senior Mechanical Engineer. Baker Group’s laboratory clients represent DNA research, biofuels, food additives, pharmaceutical, healthcare and manufacturing.

Jim Cooper, Mechanical Design Engineer, adds, “As one of our employees said, most construction projects aren’t rocket science. But clients who work with things like DNA at the molecular level are dealing with rocket science. The things they do make the world a better place. Our role is to engineer and build their mechanical, electrical and automation systems in ways that give them consistency and eliminates variables. This helps them have success more quickly.”

Job No. 1: Understand Client Needs & Regulatory Requirements

As with every project, Baker Group’s laboratory projects begin with learning what will most benefit the client and what regulatory agency requirements are involved.

Cooper says, “For example, we’re often asked to incorporate a piece of equipment that our client fabricated themselves or purchased. We research what they really need early in the process – we know the questions to ask so that we get it right without mistakes being made later.”

Baker Group’s laboratory team then digs deep into regulatory agencies’ requirements and procedures.

For instance, drug manufacturers have FDA and/or USDA requirements. The manufacturing and healthcare sectors have a host of clean air, clean plumbing, clean duct work and other requirements to eliminate risk of contamination. Food processors have requirements related to biosafety and security.

Therefore, Baker Group not only designs and builds laboratories according to stringent standards, it also modifies processes when the rules change.

“It’s incredibly complex, but we do this every day. We provide the level of quality our clients need, and we do it efficiently – it’s not trial and error,” Seymour adds.

Just How Complex?

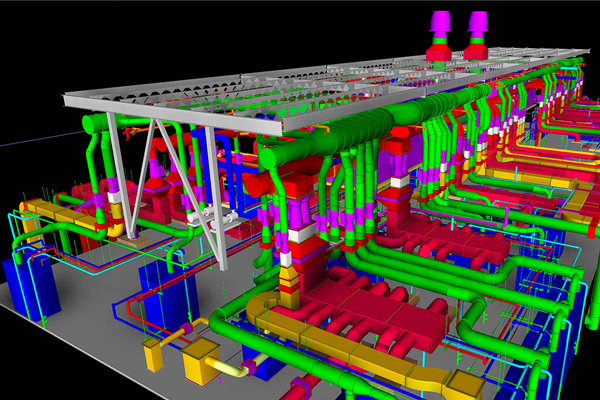

Below is a small sampling of laboratory projects for which Baker Group provided mechanical, sheet metal, plumbing, piping, electrical, automation controls, fire and security and/or service:

- Clean (contaminant-free) rooms for food production facilities, pharmaceutical mixing rooms and manufacturing plants. For example, Baker Group engineers designed mechanical systems for a 35,000-sq.ft. clean room for a manufacturer making parts so small that a single speck of dust would ruin a part.

- Custom-made environmental chambers for agricultural grow areas that lower incidence of disease and increase production outcomes. “In addition to our more traditional ag clients, we’ve recently translated our knowledge about growth chambers to the cannabis world. Our clients, who have facilities across the U.S., are finally getting the results they need,” says Cooper.

- Plumbing systems that are impervious to acid waste or water purification systems such as reverse osmosis/deionization (RO/DI) or acid injection pH balancing.

- Ventilation systems for hospital operating rooms, histology labs and other healthcare settings needing to keep contaminants out of the air to ensure the safety, quality and efficiency of procedures or experiments.

Test, Test & Retest

After construction and commissioning, some owners require that the facility be validated, which involves creating documentation for regulatory agencies stating the laboratory performs as intended. The regulatory agency may inspect paperwork and require annual updates to prove products are being manufactured in a compliant facility.

Seymour adds, “It’s a huge advantage to the owner to have all mechanical and electrical infrastructure services under one roof. We’re responsible for making it all work.”

About Baker Group

Founded in 1963 and with 650 employees across Iowa, Baker Group is the Midwest’s premier full-service specialty contractor providing mechanical, sheet metal, electrical, compressed air, building automation, process automation, security systems, fire alarm systems, parking/revenue controls and 24/7/365 service. For more information, call 855.262.4000 or visit https://www.thebakergroup.com/.